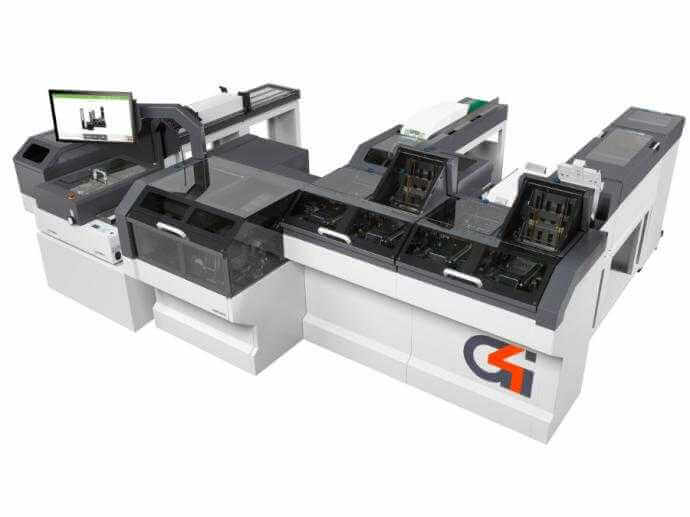

DS-1200G4i Folder Inserter

Sophisticated mail processing

Designed to automate almost every high-volume mail assembly application, the DS-1200G4i delivers best-in-class performance and the smallest footprint of any production-level solution on the market. Whether your mail pieces are transactional, marketing or highly personalized communications, the DS-1200G4i outperforms the competition every step of the way, from intuitive paper loading to predictive intelligence that estimates when the job will be completed.

Available with several insertion and accumulation speed options, as well as a wide range of feeding modules and reading capabilities, Quadient has a configuration to suit every need.

When assembling mail with variable pages, the DS-1200G4i's state-of-the-art feeding technology, IMOS operating system, and Automated Insertion Management System (AIMS) guarantee the right documents are inserted into the correct envelope.

The DS-1200G4i can read any type of coding including optical mark, optical character, and 1D and 2D data matrix barcodes. The automated camera adds flexibility by automatically adjusting to the individual mark locations of a particular job.

When integrated with our Impress Automate document creation and automation solution, the DS-1200G4i provides you with total control over every step of your mail creation processes.

Why choose the DS-1200G4i?

Optimized, intelligent mail assembly

Intelligent

The DS-1200G4i’s fully automatic job change enables operators to switch from one job to another in minutes, creating large quantities of mail involving different document and envelope sizes, in a single day. The DS-1200G4i guarantees the right documents are inserted into the correct envelope by recording each document at input, then tracking every movement of each document until the mail piece is assembled. Quadient's Automated Insertion Management System (AIMS) electronically matches each mail piece to the project's mailing data file, confirming that what you wanted to put into each envelope was correctly inserted. If an error does occur, AIMS will identify the mail piece affected, the feeder the error originated from and where the error occurred in the assembly process ensuring you can correct the problem quickly and get your mail sent out on time. Quadient's Impress Automate document creation solution significantly enhances the efficiency of your mail assembly process by automating barcode creation on your documents prior to printing. The DS-1200G4i reads the barcodes to assemble variable-page mail pieces accurately. Merge different documents for the same customer into one envelope to save money on postage costs and supplies.

Accommodates variety

A variety of inserts, from flyers and BRE’s through to thick booklets and even CDs can be fed from a range of up to 16 insert feeders, each featuring fully automated separation adjustment for rapid job change. Document and insert feeders can be located anywhere on the system to create custom configurations to suit the needs of any organization. Along with the familiar feeding and folding options for processing documents and inserts into #10 and 6" x 9" envelopes, the DS-1200G4i offers full format modules for handling flats. After reading and accumulation, the system determines which size envelope the mail piece should be inserted into, based on your established criteria. The full format module is capable of inserting up to 72 pages, plus up to eight inserts, and can be used in three different modes of operation.

Always accurate

Each feeder on the DS-1200G4i calibrates the first document fed and checks each subsequent document to guarantee no double-feeds. As documents are passed from module to module, creating the finished mail piece, an electronic log is simultaneously created to record the precise progress of each document. As each process is successfully carried out, a confirmation is sent back along the modules, allowing the next process to be commenced. Should an envelope fail to open due to manufacturing or loading issues, the DS-1200G4i will reject it and continue inserting without stopping, guaranteeing accuracy. Our Automated Insertion Management System (AIMS) enhances the DS-1200G4i's built-in document accuracy to deliver end-to-end assembly verification. AIMS confirms that every piece of mail in your job has been assembled correctly, providing complete closed loop, piece-level content accuracy.

Easy to use

Every application is easily programmed using the touch screen display, with minimal technical knowledge required. Simply create a new job, identify the documents for the mail piece, select how you want them to be read, collated and inserted, and the system will adjust automatically to run the application. Even changing envelope sizes and insert thickness settings is completely automatic and done in less time than it takes to load a feeder. The simplicity of the user controls mean that set up time for new or recurring jobs is reduced to seconds rather than hours. High capacity removable trolleys can be loaded off-line, directly from a printer, while the system is running. This avoids stopping production and makes the logistics of moving documents around your mail room easier.

Integrated

The DS-1200G4i’s dynamic envelope printing solution allows you to personalize envelopes as part of the mail assembly process. When printing in matched mode, each document is recorded by the DS-1200G4i at the input stage. Once the documents have been folded and inserted, the system prints the matched name and address on the closed face envelope. Dynamic envelope printing lowers your envelope costs by eliminating the need for windowed envelopes and further ensures content accuracy by integrating the address process into your mail assembly process.

Specifications

| Assembly speed | Up to 12,000 mail pieces per hour |

| Document feeding capacity | Up to 5,000 sheets |

| Insert feeder capacity | Up to 6,000 sheets |

| Envelope feeder capacity | Up to 2,000 envelopes - Up to 500 flats |

| Compatible envelope types | #10, 6" x 9", flats |

| Automatic job set up | Standard |

| Intuitive document loading | Standard |

| Paper present sensors | Standard |

| Variable document feeding | Standard |

| Load-on-the-fly feeding | Standard |

| Document misfeed detection | Standard |

| Automatic speed adjustment | Standard |

| Instant job recall | Unlimited job programming and recall |

| Remote operator support | Standard |

| Multi-code reading technology | Standard |

| Instant job recall | 24" PC- based colour touch screen |

| Remote operator support | Standard |

| Multi-code reading technology | Standard |

| Control panel | 24" PC- based colour touch screen |

| PC operating system | Windows 10 |

| Automatic stand by | Standard |

| Accumulation before folding | Standard |

| Collation after folding | Standard |

| AIMS folder inserter audit software | Standard |

| Add-on options | |

|---|---|

| Assembly speed upgrade | Available |

| Track unit | Available |

| Feeder folder | Available |

| Document feeder | Available |

| Document accumulator | Available |

| Sheet diverter | Available |

| Insert feeder | Available |

| Full format module | Available |

| Multi-code reading | Available |

| High-capacity mail piece conveyor | Available |

| High-capacity vertical stacker | Available |

| Envelope diverter bins | Available |

| Insert n' print envelope printing kit | Available |

| Insert n' mail kit | Available |

| System dimensions | |

| Length x width x height | As per configuration specified |

| Weight | As per configuration specified |

“The DS-1200 folder inserter was the ideal solution to fulfill our customer’s increasing volume output. In one month, one of our customer’s facilities processed more than 207,000 pieces using the DS-1200.”

DS-1200G4i related products and services

Quadient Impress Automate

Automate your customer communication workflow to send documents through any combination of channels - print, digital or outsourced.

iAddress

Unlock the power of Canada Post recognized address accuracy. Clean, validate and enhance your business addresses.

Automated Insertion Management System

Verify that every of mail piece in your assembly job has been completed accurately.

Contact Us

Designed to automate almost every high-volume mail assembly application, the DS-1200G4i delivers best-in-class performance and the smallest footprint of any production-level solution on the market. Whether your mail pieces are transactional, marketing or highly personalized communications, the DS-1200G4i outperforms the competition every step of the way, from intuitive paper loading to predictive intelligence that estimates when the job will be completed.

Available with several insertion and accumulation speed options, as well as a wide range of feeding modules and reading capabilities, Quadient has a configuration to suit every need.

When assembling mail with variable pages, the DS-1200G4i's state-of-the-art feeding technology, IMOS operating system, and Automated Insertion Management System (AIMS) guarantee the right documents are inserted into the correct envelope.

The DS-1200G4i can read any type of coding including optical mark, optical character, and 1D and 2D data matrix barcodes. The automated camera adds flexibility by automatically adjusting to the individual mark locations of a particular job.

When integrated with our Impress Automate document creation and automation solution, the DS-1200G4i provides you with total control over every step of your mail creation processes.